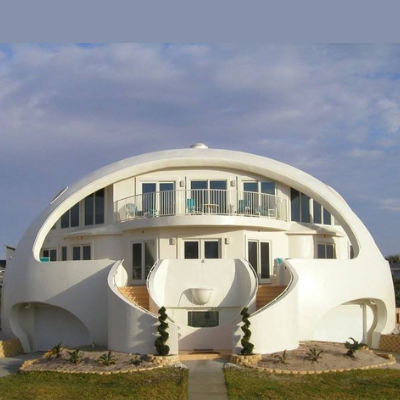

Monolithic Dome Dewellings

With the rapid speed of human development there is a proportional increase in environmental imbalance. Henceforth, sustainable building solutions are a necessity of future as well as present. Today, Architect Lubna Fatima will brief us about one such remarkable sustainable solution i.e. Monolithic Dome.

The monolithic domes a paradigm shift in construction technology. They are built for Homes, Schools, Sports facilities, Churches, Bulk storages and more. Hundreds of monolithic domes have been build all over the globe. This construction process was invented in 1975 by David B. South and his brothers Berry and Randy.

All monolithic domes regardless of size and design are build using same construction process.

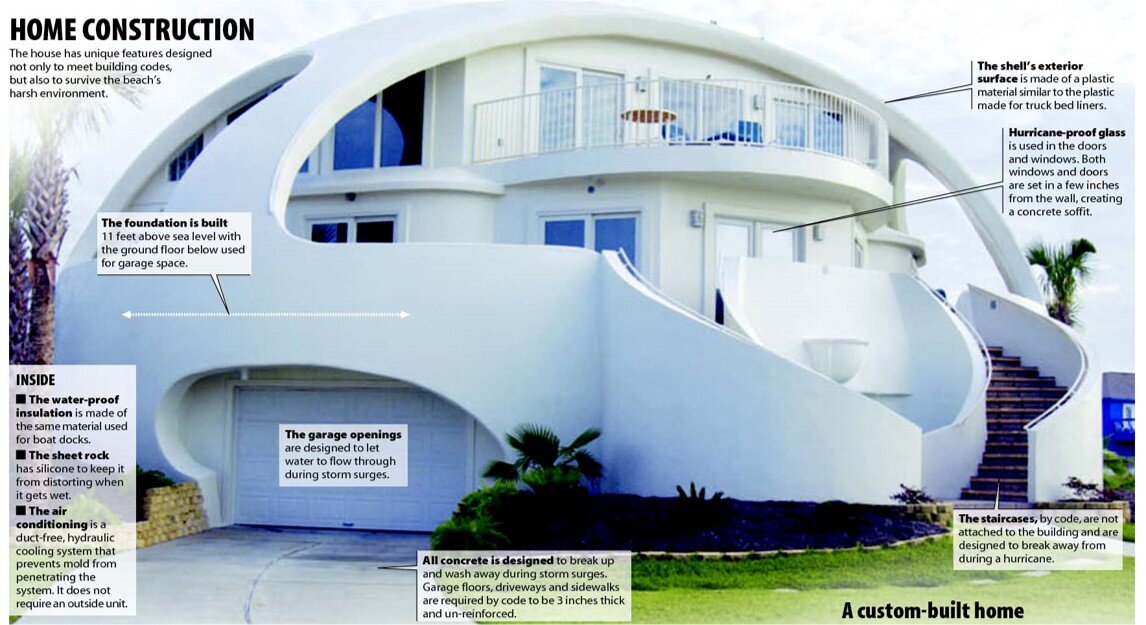

The dome starts as a concrete ring beam foundation reinforced with steel rebar giving the dome the structural integrity needed to with stand fires and disasters. Vertical steel bars embedded in the ring are later attached to the steel reinforcement of the dome itself. Small domes may use an integrated floor ring foundation otherwise the floor is poured after completion of the dome.

A custom designed airform made from a PVC coated fabric is attached to the ring beam. It is inflated with fans to the specified pressure usually two inches of water column. The air form assumes the shape of the structure. Fans maintain the pressure on the airform and continue to run throughout the construction of the dome shell.

Approximately 3” of polyurethane foam, considered by many to be the world’s best insulation is sprayed on to the interior of the airform.

Special rebar hangers are embedded into the foam which provide the base for attaching the steel reinforcing bar.

Rebar attached to the foam and especially engineered horizontal and vertical pattern, the size and amount of rebar used depends upon the purpose and size of the structure. For example, large domes require large bars with small spacing while small domes require small bars at larger spacing.

Next, shortcrete, a super strong spray mix of concrete is sprayed onto the interior surface of the dome. The steel rebar is embedded in the concrete. Thickness of the concrete depends on the size and purpose of the building, an average of 3” for a home and 2’ thick for heavy-duty bulk storage facility.

Once the concrete is set the fans are shut off and the monolithic dome shell is complete. The airform is left on the dome as a single ply roofing membrane which acts as a vapor barrier and protects the foam from harsh ultraviolet rays. As an option over the airform the dome can be coated using a variety of different coatings. As each step in the construction process is completed the dome gets stronger. Its full strength is realized after all the concrete is set.

Monolithic domes are strong, energy efficient, cost effective and permanent. All monolithic domes regardless of their shape and size or purpose share common benefits. They can be built to meet the Federal Emergency Management agency’s definition of a structure that provides near absolute protection and therefore can be used as shelters when disaster strikes. Italy high school in Italy Texas has a tornado shelter disguised as a gymnasium. From Friday September 29th to Sunday October 1st 1999 Hurricane Keith a force 5 hurricane with winds up to 135 miles/hour raised over ambergris key off the coast of Elise in the Caribbean Sea, two monolithic domes in the area survived Hurricane keys fury virtually unscathed. Island residents took refuge in the dome while property around them was decimated. Security is just one reason many people are choosing monolithic domes. Energy efficiency is another. Concrete and foam in a monolithic dome work together as a large thermal battery which maintains even interior temperatures, it therefore takes 50-75% less energy to heat & cool monolithic domes compared to similar sized conventional structures. In 1984 Maranatha Church in Montpelier Texas built a 34,000 sq.ft dome sanctuary and has since reported significant energy savings. Over the lifetime of a monolithic dome energy-efficiency amount to huge savings generally the value of the dome over 20 years. Savings can also be realized in construction, maintenance and insurance costs. Facing School in Payson Arizona built a 200’ diameter gymnasium in 1997 which cost 2.9 million dollars far less than the 6 million dollars the nearby community of White River Arizona spent for a comparable traditional facility, making the monolithic dome approximately 50% less to construct than the conventional gym.

Because the monolithic domes cannot be destroyed by fire, tornado, hurricane, earthquake, termites or mold they cost less to insure in addition considerable savings can be generated because of the domed strength. Conveyors, large scoreboards, machinery, heavy lighting fixtures and other equipment can be safely hung from the dome shell without additional internal structural support. The Pantheon in Rome Italy is the monolithic domes oldest cousin built in 126 AD, its dome measures a 143’ in diameter. For centuries it was the largest single-span dome in the world, it is still used today. Over the years as needs change a monolithic dome may need remodeling and a coat of paint but not replacement. With minimal maintenance the lifetime of monolithic dome is measured in centuries. To sum up the monolithic dome benefits, they are disaster resistant, energy efficient, cost effective and permanent.

We often see portrayals of the future where the architecture is primarily domes, the future is now. The monolithic dome is truly tomorrow’s building available today.